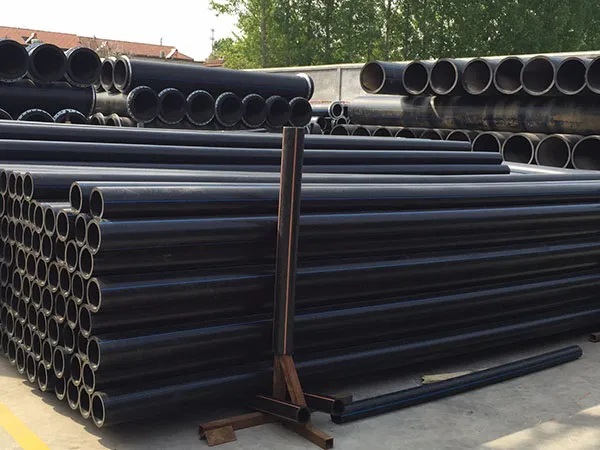

Thick wall ultra-high molecular weight polyethylene (UHMWPE) pipe is a specialized engineering thermoplastic piping system known for its exceptional properties, making it ideal for demanding industrial applications.

Thick wall ultra-high molecular weight polyethylene (UHMWPE) pipe is a specialized, high-performance piping solution designed to withstand the most aggressive industrial environments. It combines the extraordinary properties of the UHMWPE polymer with an increased wall thickness to deliver unparalleled durability, longevity, and operational efficiency in applications where other materials quickly fail.

UHMWPE is a type of polyethylene polymer with an average molecular weight significantly higher than conventional HDPE (High-Density Polyethylene), typically exceeding 3.1 million g/mol (as defined by ASTM D4020). This "ultra-high" molecular weight results in extremely long polymer chains that are highly entangled, giving the material its unique combination of characteristics.

Exceptional Wear and Abrasion Resistance: This is the most significant advantage of UHMWPE. It exhibits superior resistance to sliding abrasion, often outperforming carbon steel, other PE pipes (like HDPE), and even nylon in abrasive slurry applications. This makes it ideal for transporting materials like mining tailings, coal ash, sand, and mud.

High Impact Strength: UHMWPE boasts the highest impact strength among all plastics. Its ability to absorb impact energy makes it highly resistant to cracking from external forces or internal pressure fluctuations and water hammer.

Excellent Chemical Resistance: With a saturated molecular structure, UHMWPE offers outstanding resistance to a wide range of corrosive media, including acids, alkalis, salts, and organic solvents. This makes it suitable for chemical processing and industrial applications where corrosive substances are transported.

Low Coefficient of Friction and Self-Lubricating: The smooth, waxy surface of UHMWPE provides an extremely low coefficient of friction (0.05-0.11), which reduces flow resistance and energy consumption for pumping. This self-lubricating property also prevents scaling and material buildup on the inner walls, saving on cleaning and maintenance costs.

Lightweight and Durable: UHMWPE pipe is significantly lighter than steel pipe (typically 1/8th the weight), which greatly reduces installation costs and logistics. Despite its light weight, it is highly durable and can offer a longer service life than traditional materials in abrasive and corrosive environments.

Temperature Resistance: UHMWPE pipes can operate across a broad temperature range, typically from -70°C to +80°C, and some can even withstand temperatures as low as -169°C.

Flexibility: UHMWPE pipes possess good flexibility and elongation (over 250%), allowing them to absorb surge pressures, vibrations, and stresses caused by ground movement, making them suitable for challenging terrains.

Non-Toxic and Environmentally Friendly: UHMWPE is colorless, odorless, and non-toxic, making it suitable for applications involving drinking water and food-grade materials. Its manufacturing process is also often cited as being more environmentally friendly than that of steel pipes.

Thick wall UHMWPE pipes typically have nominal diameters ranging from 65mm to 1200mm, with wall thicknesses usually between 8mm and 45mm. They can handle nominal pressure ratings from 0.6 MPa to 2.0 MPa, with composite UHMWPE pipes capable of reaching up to 6.4 MPa.

The unique combination of properties makes thick wall UHMWPE pipes a preferred choice in various industries:

Mining: Slurry transportation (tailings, coal water slurry, mineral slurries), dewatering, and general process piping.

Dredging: Transport of sand, mud, and other dredged materials.

Power Generation: Ash and slag disposal, coal water slurry transport.

Chemical Processing: Transport of corrosive chemicals and acids.

Water and Wastewater Treatment: Water supply, sewage, and effluent discharge lines due to corrosion resistance and long service life.

Agriculture: Irrigation systems.

Salt Production: Brine transportation.

Food and Drug Processing: Conveying solid particles like flour, brewing raw materials, and oils due to their hygienic and non-toxic nature.

In summary, thick wall UHMWPE pipe offers a highly durable, efficient, and cost-effective solution for conveying abrasive, corrosive, and challenging materials in a wide range of industrial and civil applications, often outperforming traditional metal and plastic piping systems.