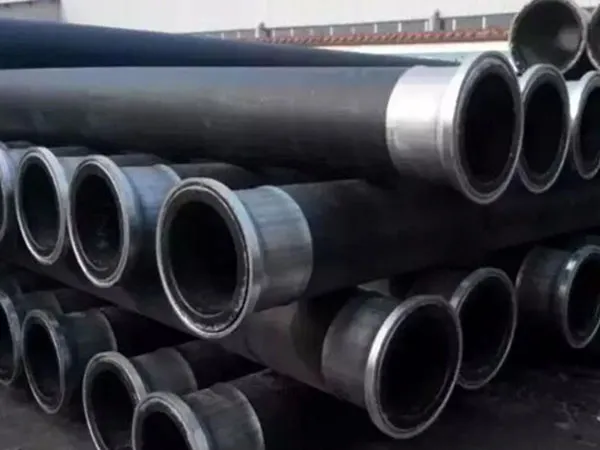

Steel reinforced thermoplastic (SRTP) pipes are advanced composite conduits that represent a significant evolution in pipeline technology. They are engineered to combine the high mechanical strength of steel with the exceptional durability, flexibility, and corrosion resistance of thermoplastic materials.

Steel Reinforced Thermoplastic Pipes (SRTP), often categorized under the broader term of Reinforced Thermoplastic Pipes (RTP), represent an advanced class of flexible composite pipelines that combine the benefits of both thermoplastic materials and high-strength reinforcement, specifically steel. They are engineered to address the limitations of traditional steel pipes, particularly concerning corrosion, weight, and installation complexity, while offering enhanced pressure capabilities and durability.

SRTP typically consist of a multi-layered structure:

Inner Thermoplastic Liner: This layer, usually made from materials like High-Density Polyethylene (HDPE), Polyamide (PA-11, PA-12), Polypropylene (PP), or Polyvinylidene Fluoride (PVDF), provides excellent corrosion and abrasion resistance. It ensures a smooth flow of the conveyed fluid and prevents chemical interaction with the reinforcement layer.

Reinforcement Layer: This is the core strength component. In steel-reinforced pipes, this layer consists of helically wound high-strength steel wires or cords. The winding angle and number of layers are carefully designed to withstand internal pressure and external loads. Other RTP types might use aramid, glass, or carbon fibers for reinforcement.

Outer Thermoplastic Jacket: An external protective layer, often made of HDPE or similar thermoplastic, safeguards the reinforcement layer from external damage, UV radiation, and environmental degradation during installation and operation.

The manufacturing of SRTP involves a continuous process where the thermoplastic layers are extruded, and the steel reinforcement wires are helically wrapped around the inner liner. This winding process is precisely controlled to achieve the desired mechanical properties and pressure ratings. The layers are then often fused together, creating a fully bonded composite structure. This continuous manufacturing allows for the production of very long lengths of pipe, which can be spooled for efficient transportation and installation.

SRTP offer several significant advantages over traditional piping materials, especially steel:

Corrosion Resistance: The thermoplastic inner liner provides exceptional resistance to corrosive fluids (e.g., sour oil and gas containing H2S and CO2, acids, alkalis) and external environmental factors, eliminating the need for costly corrosion protection and extending service life.

High Pressure Capability: The steel reinforcement significantly enhances the pipe's ability to withstand high internal pressures, often comparable to or exceeding that of traditional steel pipes.

Flexibility and Spoolability: Unlike rigid steel pipes, SRTP are highly flexible and can be manufactured in long, continuous lengths (up to several kilometers). This allows for easier handling, transportation (coiled on reels), and rapid installation, including trenchless methods, reducing the number of joints and potential leak points.

Lightweight: SRTP are considerably lighter than steel pipes of equivalent pressure rating, leading to lower transportation costs, easier handling on-site, and reduced need for heavy lifting equipment.

Durability and Long Service Life: The combination of corrosion-resistant thermoplastics and robust steel reinforcement results in pipes with an extended service life, often exceeding 20-50 years, with minimal maintenance requirements.

Reduced Installation Costs: The flexibility, long lengths, and lightweight nature contribute to faster and more cost-effective installation compared to conventional steel pipelines.

Smooth Inner Wall: The smooth thermoplastic interior reduces friction, leading to improved flow characteristics and resistance to scaling, which can enhance flow rates and reduce energy consumption.

SRTP are widely used in various demanding industries and applications, including:

Oil and Gas Industry:

Gathering and transmission lines for crude oil, natural gas, and refined products.

Water injection lines for enhanced oil recovery.

Sour service applications (containing H2S and CO2).

Offshore and subsea pipelines.

Wellhead and X-tree connections.

Water and Wastewater Management:

High-pressure water supply lines.

Potable water distribution.

Wastewater and sewage transfer.

Trenchless installations for urban infrastructure.

Mining:

Transportation of corrosive slurries and process water.

Underground drainage and fire sprinkler systems.

Chemical and Geothermal Industries:

Safe transport of aggressive chemicals and geothermal fluids.

Other Applications:

Municipal pipes (drainage, sewer).

Construction pipes (hot gas, mud, slurry, coal transmission).

The steel-reinforced thermoplastic pipes offer a compelling solution for modern pipeline infrastructure, combining the best attributes of plastics and steel to deliver high performance, durability, and cost-effectiveness in challenging environments.