HDPE stands for High-Density Polyethylene. It is a thermoplastic polymer made from petroleum.

HDPE pipe is a flexible plastic pipe used for fluid and gas transfer. It is known for its high strength-to-density ratio, making it lightweight yet incredibly tough and durable.

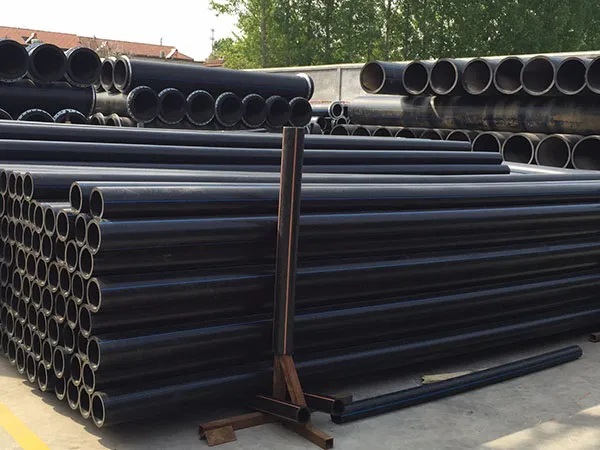

The color often indicates the pipe's intended application, though standards can vary by region. Common conventions include: Solid Black: The most common color, often used for industrial, water, and wastewater applications. Black with Blue Stripes: Potable (drinking) water. Solid Yellow or Black with Yellow Stripes: Natural gas or propane gas distribution. Solid Green or Black with Green Stripes: Sewer and wastewater. Solid Orange or Black with Orange Stripes: Telecommunications and electrical conduit. Solid Purple or Black with Purple Stripes: Reclaimed water (non-potable). Solid White: Often used for irrigation or drainage.

HDPE pipe is chosen for its many benefits: Leak-Free Joints: When joined by heat fusion, the joints become as strong as the pipe itself, creating a monolithic, leak-proof system. Flexibility: It can be bent to a radius of 20-25 times its outside diameter, reducing the need for fittings and allowing it to be installed around obstacles and in shifting soils. Chemical & Corrosion Resistance: HDPE is virtually inert and does not rust, rot, or corrode. It's highly resistant to acids, bases, and many chemicals. Durability & Impact Resistance: It is highly resistant to abrasion and can withstand significant impacts, even at low temperatures, without cracking. Long Service Life: The design life for HDPE pipe is conservatively estimated to be 50-100 years. Lightweight: It is much lighter than materials like steel, concrete, or ductile iron, making it easier and cheaper to transport and install. Trenchless Installation: Its flexibility and strength make it the ideal material for trenchless installation methods like horizontal directional drilling (HDD), pipe bursting, and slip-lining.

With proper design, installation, and operation, HDPE pipe has a service life of 50 to 100 years. Its resistance to common failure modes like corrosion and fatigue contributes to its longevity.

Yes. High-quality, pressure-rated HDPE pipe contains carbon black (which makes it black) as a UV inhibitor. This allows the pipe to be used and stored above ground without significant degradation from sunlight for many years. Non-black pipes may have a shorter UV exposure limit.

The most common and effective method is heat fusion. This process involves heating the ends of two pipes (or a pipe and a fitting) to a molten state and then pressing them together to form a permanent, monolithic joint. The two main types of heat fusion are: Butt Fusion: The most common method for joining pipe ends of the same diameter. The pipe ends are heated with a special tool and then pressed together under a specific pressure until they cool, creating a single, continuous pipe. Electrofusion: This method uses a special coupling (fitting) that has embedded heating coils. The pipe ends are inserted into the fitting, and an electric current is run through the coils, melting the inside of the fitting and the outside of the pipe to form a fused joint. This is often used for repairs or tie-ins. Mechanical Fittings: Flanges, mechanical joint adapters, and compression couplings can also be used to connect HDPE to other pipe materials (like steel or ductile iron) or to valves and pumps.

SDR stands for Standard Dimension Ratio. It is a numerical value that represents the ratio of the pipe's average outside diameter to its minimum wall thickness. SDR = (Outside Diameter) / (Wall Thickness) The key takeaway is: A lower SDR number means a thicker pipe wall and a higher pressure rating. For example, an SDR 9 pipe has a thicker wall and can handle more pressure than an SDR 17 pipe of the same diameter.

The pressure rating is directly related to the pipe's SDR and the material used (e.g., PE4710). For a given material, a lower SDR corresponds to a higher pressure rating. This information is always available from the pipe manufacturer's technical data sheets.

HDPE pipe is extremely versatile and is used in a wide range of industries: Municipal: Potable water distribution, sewer mains, and storm drainage. Industrial: Chemical processing, slurry transport, and cooling water lines. Oil & Gas: Natural gas distribution, crude oil collection, and produced water lines. Mining: Tailing lines, dewatering, and solution mining. Agriculture: Irrigation and drainage systems. Geothermal: Ground source heat pump systems. Conduit: Protecting fiber optic cables and electrical lines.