High-density polyethylene (HDPE) pipe has become the material of choice for a vast range of applications within the modern coal mining industry. Its unique combination of physical properties makes it exceptionally well-suited to the harsh, demanding, and safety-critical environment of a mine. This introduction covers what HDPE pipe is, its key advantages, its primary applications in coal mining, and important technical considerations.

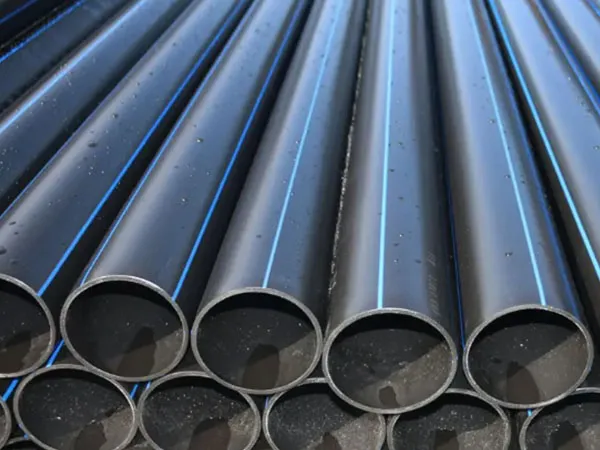

HDPE coal mine pipe is a type of plastic pipe specifically manufactured from high-density polyethylene, a robust thermoplastic material. These pipes are engineered to meet the demanding conditions found in coal mining environments, including resistance to abrasion, corrosion, impact, and fluctuating pressures. A key characteristic for coal mining applications is that these pipes are often designed with anti-static and flame-retardant properties to ensure safety in potentially explosive environments.

Durability and Longevity: HDPE pipes are highly resistant to corrosion from acidic or alkaline substances often encountered in mines, as well as abrasion from slurries and solid particles. This significantly extends their lifespan, often estimated between 50 to 100 years, reducing the need for frequent replacements.

Flexibility and Toughness: The semi-rigid and flexible nature of HDPE allows it to adapt to uneven terrain and ground movement, which is common in mining areas.

This flexibility also reduces the need for numerous fittings and can withstand pressure surges (water hammer), which are common in pumping systems.

Leak-Proof Joints: HDPE pipes are typically joined by heat fusion (butt fusion or electrofusion), creating a seamless, monolithic system that is as strong as or stronger than the pipe itself. This eliminates leak points, preventing material loss, environmental contamination, and ensuring efficient fluid transport.

Lightweight: HDPE is significantly lighter than traditional metallic pipes (about one-eighth the density of steel), making transportation, handling, and installation much easier and more cost-effective.

Chemical Resistance: HDPE is inert to most chemicals, making it ideal for transporting a wide range of corrosive solutions and slurries, including those with a pH range of 2 to 12.

Abrasion Resistance: HDPE's smooth inner wall reduces friction and allows for higher flow velocities, keeping particles suspended in slurries and minimizing wear on the pipe walls. Studies have shown HDPE to be 3-5 times more abrasion-resistant than steel in certain applications.

Cost-Effectiveness: While initial material costs might sometimes be comparable or slightly higher than other materials, the lower installation costs (due to lighter weight, fewer fittings, and alternative installation methods like trenchless technologies), reduced maintenance, and longer service life result in significant overall life-cycle cost savings.

Safety Features: For coal mining, specific HDPE pipes are produced with flame-retardant and anti-static additives to minimize risks in flammable and explosive atmospheres.

Environmental Sustainability: HDPE is a recyclable material, and its leak-free nature helps prevent environmental contamination.

HDPE pipes are extensively used in various critical applications within coal mining:

Water Supply and Drainage Systems: Essential for providing water for various mining processes and for efficient removal of mine water (dewatering).

Slurry Transportation: Used for conveying ore concentrates, tailings (waste material mixed with water), and other abrasive slurries.

Gas Drainage Systems: Crucial for safely extracting and managing methane and other gases from coal seams, enhancing mine safety.

Ventilation Conduits: Employed as positive and negative pressure air pipes for mine ventilation.

Dust Suppression Systems: Used to deliver water or other solutions for dust control.

Process Water and Heap Leaching: For transporting process water in various mineral recovery processes, including heap leaching.

HDPE pipes for coal mining adhere to various international and national standards to ensure quality and safety. These may include:

ISO 4427: Polyethylene (PE) pipes for water supply.

EN 12201: Plastic piping systems for water supply.

AS/NZS 4130: Polyethylene (PE) pipes for pressure applications.

ASTM D3035 / F714: Standard specifications for polyethylene plastic pipe.

ASTM F2620: Standard practice for heat fusion joining of polyethylene pipe and fittings.

MT588.1-2005 (Part 1: PE pipe), MT181-88, AQ1071-2009: National coal industry standards in some regions for safety regulations on plastic mining pipes, often specifying anti-static and flame-retardant properties.